Blog Post 5: Material Selection

- Sam Jones

- Mar 15, 2020

- 2 min read

Updated: Aug 5, 2020

Choosing the right materials to suit the intended use of each device is going to prove crucial in this project. This is why I have carried out research into the properties of materials commonly used in 3D printing/machining techniques, taking into account those currently available for use in the university's facilities.

TangoBlack: After consulting with one of the lecturers in charge of managing the engineering department's Connex 3D printer, I decided that this would be the best rubber-type material for producing high-friction components such as traction pads.

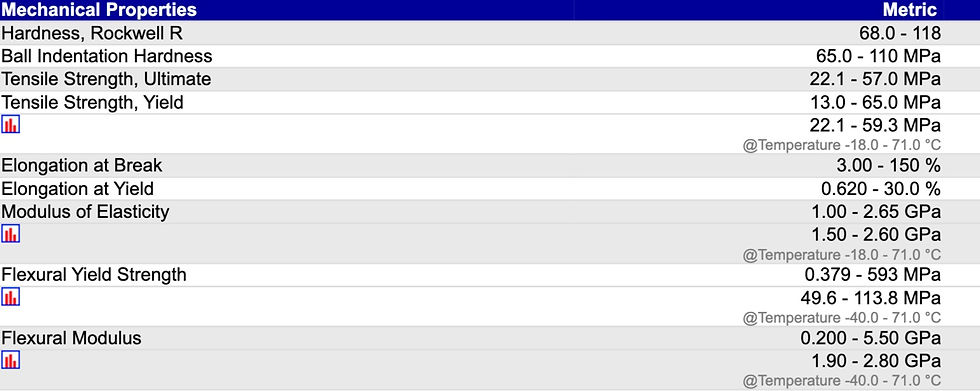

There are 2 plastics I am considering for use in my working prototypes: PLA and ABS. You will find relevant properties of both materials below.

PLA:

PLA is arguable the most widely used 3D printing filament and is extremely popular for use in early prototyping applications. Its low melting point and negligible warping makes it extremely easy to print, the downside to this being its susceptibility to major loss of strength and stiffness at temperatures exceeding 50 degrees celsius. Along with this, PLA is notably brittle, meaning that any components printed with this filament will have poor durability and impact resistance.

ABS:

Although it is weaker and less rigid than PLA, ABS boasts higher toughness and durability. It is also 25% lighter than PLA with 4x higher impact resistance. It is worth noting that because ABS is more heat resistant and prone to warping, special care must be taken when printing in the form of a heated bed and an extruder with higher temperature capabilities. The improved durability seen in ABS makes it more suitable for working prototypes compared to PLA and coupled with being lighter, I think it would make sense to use it for all components across the 3 design concepts. As for gear material, aluminium alloy 5052 seems like the best choice seeing as it has medium to high strength, machines well and has excellent resistance to corrosion - it is commonly seen in marine applications and so will not have a problem with any liquids it may come into contact with.

Comments